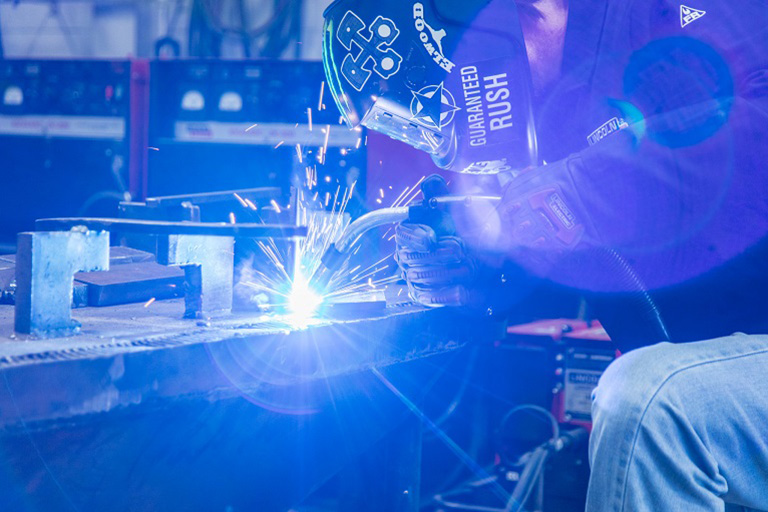

Discover materials and techniques for work in many industries as a specialist in one of the most highly paid skilled trades.

What is Welding Technology?

Welding occupations are primarily concerned with joining, surfacing, or repairing structures or parts made of metal or other weldable materials. The skills and knowledge needed to determine the appropriate welding technique required for a specific project and to successfully perform that technique are gained through course work and practical experience. Classes are available online and in person at the Leestown and Danville Campuses and in evening at Madison Area Training Center.

- For information about the Welding Program at Danville Campus, please contact Bobby Coffey at (859) 246-6888 or bobby.coffey@kctcs.edu.

Demand for welders is growing steadily. Average wages start in the range of $17 to $25 hourly with more earning potential for specialized certifications or complex roles. Graduates of the program are hired by local factories, construction companies, and small businesses including Donaldson's, Intelligrated, Link-Belt, RJ Corman, and more.

BCTC's Welding Technology Program offers a combination of lab and lecture classes with real world applications, perfect for students who enjoy hands-on work and a non-traditional classroom environment.

BCTC's Welding Technology Program prepares students for the workforce by teaching them the various welding techniques focusing on joining weldments, surfacing, and repairing structures while using state-of-the-art equipment.

Welding is a highly skilled trade that offers a wide variety of high demand job opportunities from construction and manufacturing to car racing.

Students in Welding Technology can earn credentials ranging from an Associate in Applied Science degree or Combination Welding Diploma as well as 11 different certificate options in specific aspects of welding.

Students have the opportunity to become members of the American Welding Society. Welding students participate in projects around campus and in the community by building signs, benches, trailers, grills, walking bridges, and sculptures.

A majority of welders work in manufacturing industries. Others are employed by construction firms and businesses performing various repair services. A skilled welder may qualify as a technician, supervisor, inspector, or as an owner of a welding business.

- ARC Cutter

- ARC Welder

- Gas Welder

- Pipeline Welder

- Production Line Welder

- Tack Welder

- Welder Helper

Getting Started

Getting Started with Welding Technology

BCTC's Welding Technology Program offers a combination of lab and lecture classes with real world applications, perfect for students who enjoy hands-on work and a non-traditional classroom environment.

Courses are offered at the Leestown Campus in Lexington and the Danville Campus. The program offers flexible class schedules to accommodate working students.

- For information about the Welding Program at Danville Campus, please contact Bobby Coffey at (859) 246-6888 or bobby.coffey@kctcs.edu.

Demand for welders is growing steadily. Average wages start in the range of $17 to $25 hourly with more earning potential for specialized certifications or complex roles. Graduates of the program are hired by local factories, construction companies, and small businesses including Donaldson's, Intelligrated, Link-Belt, RJ Corman, and more.

What are my degree, diploma, and certificate options?

The catalog describes the course requirements for completing the credential. Students are required to schedule an appointment with their assigned academic advisor to ensure achievement of their academic goals.

How Do I Pay For This?

What Else Do I Need to Know?

Additional Information

We offer state welding certification exams through our Workforce Solutions department.

For more information, please call (859) 246-6666.

Our Welding Technology curriculum has been designed to provide a balanced learning experience. Lecture and lab courses are used to enhance learning and provide necessary applied experiences.

Each course is structured to prepare students for the next more advanced course as they move through the program.

The use of new technology, as well as computer skills, are a large part of the educational experience. These skills are also needed for future advancement in the Welding field.

- WLD 100 - Oxy-Fuel Systems

- WLD 101 - Oxy-Fuel Systems Lab

- WLD 120 - SMAW

- WLD 121 - SMAW Fillet Lab

- WLD 123 - SMAW with Backing Lab

- MAT 116 - Technical Mathematics

- WLD 140 - GMAW

- WLD 141 - GMAW Fillet Lab

- WLD 143 - GMAW Groove Lab

- WLD 151 - Basic Welding A

- WLD 170 - Blueprint Reading

- WLD 171 - Blueprint Reading Lab

- ENG 101 - Writing

- COM 181 - Communications

- CPU 150 - Computer Fundamentals

- ART 100 - Intro to Art

- WLD 130 - GTAW

- WLD 131 - GTAW Fillet Lab

- WLD 133 - GTAW Groove Lab

- SOC 101 - Sociology (Example)

- WLD 220 - Weld Certification

- WLD 221 - Weld Certification Lab

- WLD 298 - Practicum

- PH 171 - Physics (Example)

- Safety Glasses

- Welding hood (auto-darking recommended)

- Leather boots or shoes

- All-leather welding gloves

- Long pants without cuffs (blue jeans or cotton work-pants)

- Welding jacket

- Welding cap (optional)

- 11" (eleven inch) locking C-clamp

- Tape measure (standard)

- Clear face-shield

- Dark face-shield

- 4-1/2" (four and a half inch) grinder

- Welders/welding pliers

- Wire brush

- Chipping hammer

- Combo square

Length of Program

You can earn an associate in applied science degree in two years if you maintain full-time status.

This information should not be considered a substitute for the KCTCS Catalog. You should always choose classes in cooperation with your faculty advisor to ensure that you meet all degree requirements.